In the fast-paced world of manufacturing, precision is not just a benchmark, it’s the standard that defines success. Whether it’s aerospace components, medical devices, or industrial machinery, every detail matters. Even a slight deviation in measurements can affect performance, safety, and reliability. That’s why companies across industries rely on professional precision engineering services to ensure their products meet the highest standards of accuracy and quality.

At the heart of this commitment to excellence stands Tuowei Precision, a trusted name known for delivering engineering services that combine innovation, expertise, and technology to bring flawless results.

What Are Professional Precision Engineering Services?

Professional precision engineering services involve designing, developing, and manufacturing components with exceptionally tight tolerances, often within microns. These services go beyond standard machining by incorporating advanced tools, detailed planning, and strict quality controls.

From CNC machining and milling to rapid prototyping and product testing, precision engineering covers every stage of product realization. The goal is to create components that not only fit perfectly but also perform consistently under demanding conditions.

At Tuowei Precision, these services are powered by state-of-the-art equipment, skilled engineers, and a deep understanding of materials and design principles, ensuring each part meets exact specifications.

Why Accuracy Matters More Than Ever

Product accuracy is more than just a measurement; it’s the key to performance, safety, and reputation. A small dimensional error can lead to malfunction, reduced efficiency, or even product failure.

Industries such as aerospace, medical, and automotive depend on precision engineering because:

- Components must integrate seamlessly with other parts.

- Systems operate under extreme stress or temperature variations.

- The margin for error is nearly zero.

In such environments, professional precision engineering services ensure every component is manufactured with perfect alignment, balance, and functionality, resulting in smoother operation, reduced wear, and enhanced durability.

How Professional Precision Engineering Enhances Product Accuracy

Precision engineering is a blend of advanced technology and expert craftsmanship. Let’s look at how professional services guarantee unmatched accuracy at every step of production.

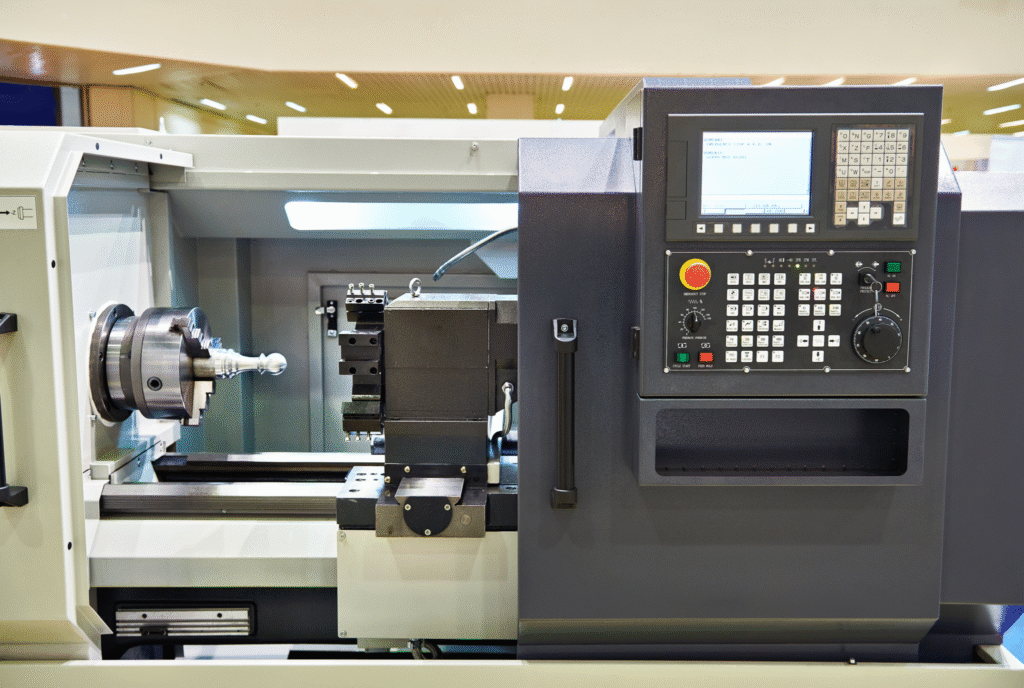

1. Advanced CNC Technology for Consistent Precision

Modern CNC machines can achieve incredible levels of accuracy by using computer-controlled cutting tools that follow exact digital designs.

At Tuowei Precision, engineers utilize multi-axis CNC systems capable of machining complex geometries in a single setup. This reduces human error, ensures repeatability, and delivers consistent accuracy across all parts, whether it’s a prototype or a full production run.

2. Rigorous Quality Control and Inspection

Accuracy doesn’t happen by accident, it’s verified through strict quality control. Tuowei’s engineers perform real-time measurements using advanced inspection tools like CMM (Coordinate Measuring Machines), laser scanners, and optical comparators.

These checks confirm that every component meets exact specifications before moving to the next stage, ensuring complete dimensional consistency and product reliability.

3. Skilled Engineering Expertise

Technology is only as good as the people operating it. Professional precision engineering combines technical knowledge with experience in material behavior, machining techniques, and design optimization.

Tuowei’s team of engineers understands how materials react under stress, how tolerances influence assembly, and how to enhance both accuracy and efficiency through smart engineering decisions.

4. Prototyping and Design Validation

Professional precision engineering isn’t just about machining, it’s also about testing and validation. Before full production begins, Tuowei offers rapid prototyping services that allow clients to see, test, and refine their designs in real-world conditions.

This process ensures that the final product is not only accurate but also optimized for performance and manufacturability.

How Precision Engineering Improves Product Quality

While accuracy ensures parts fit and function correctly, overall product quality determines how well they perform over time. Here’s how professional precision engineering services enhance both immediate and long-term product quality.

- Improved Reliability: Consistent manufacturing means fewer defects and longer-lasting parts.

- Superior Performance: High-precision components reduce vibration and improve mechanical efficiency.

- Better Aesthetics: Fine surface finishes and precise details enhance both functionality and appearance.

- Reduced Maintenance Costs: Fewer failures mean less downtime and longer equipment life.

- Increased Customer Trust: Quality products strengthen brand reputation and customer confidence.

When precision engineering is done right, quality becomes a natural outcome, not a challenge.

Tuowei Precision: Where Expertise Meets Excellence

For over a decade, Tuowei Precision has been helping companies transform concepts into flawless, high-performance products. Their professional precision engineering services combine innovation, skill, and cutting-edge technology to achieve unparalleled accuracy and reliability.

Tuowei’s engineers work closely with clients from concept to completion, offering tailored solutions that meet the unique demands of each project. Whether you need tight-tolerance CNC machining, complex assemblies, or rapid prototyping, Tuowei delivers results that exceed expectations, every time.

Their core philosophy is simple: precision today ensures perfection tomorrow.

Conclusion: Power Your Products with Tuowei Precision

In an era where accuracy defines quality, professional precision engineering services are the cornerstone of successful manufacturing. They ensure every product functions as designed, lasts longer, and performs better.

With Tuowei Precision as your engineering partner, you gain access to expertise, technology, and dedication that push the boundaries of what’s possible.

Ready to take your product quality to the next level?

Partner with Tuowei Precision, a reliable CNC manufacturer trusted by global industries.

You can also learn more about Tuowei to explore how their professional precision engineering services bring innovation and accuracy together for superior results.