In today’s fast-paced world of product design and innovation, speed and precision are everything. Companies are constantly under pressure to launch better products faster, without compromising on quality. But how do you test, refine, and perfect a design before committing to mass production? The answer lies in rapid prototyping services. the essential bridge between concept and production.

From startups developing their first prototypes to global manufacturers launching new product lines, rapid prototyping has become a critical step in modern product development. Let’s explore why this technology is so important and how it helps businesses stay ahead in a competitive market.

What Is Rapid Prototyping?

Rapid prototyping refers to the process of quickly fabricating a physical model of a part or product using advanced manufacturing techniques such as CNC machining, 3D printing, or vacuum casting. The goal is to turn digital designs into tangible, functional prototypes that can be tested, analyzed, and improved.

Unlike traditional manufacturing, which can take weeks or even months, rapid prototyping drastically reduces production time allowing teams to experiment, validate, and refine their designs in just days.

Why Rapid Prototyping Services Matter More Than Ever

1. Speeding Up Product Development Cycles

Time-to-market is a critical factor for business success. The faster you can move from idea to prototype, the sooner you can test, iterate, and launch your final product.

Rapid prototyping services enable designers and engineers to produce accurate models within days, not weeks. This agility means companies can collect feedback early, fix issues quickly, and move forward with confidence. In competitive industries, shaving weeks off your development cycle can make a major difference.

2. Reducing Design Risks and Errors

It’s one thing to design a perfect model on a computer screen but real-world performance often tells a different story. Rapid prototyping gives engineers the chance to spot potential design flaws before mass production begins.

By testing a physical prototype, teams can evaluate fit, function, and performance. Adjustments can then be made immediately, saving enormous time and money that would otherwise be lost to retooling or redesigning after production starts.

In short, rapid prototyping helps you fail fast and fix faster.

3. Encouraging Innovation and Creativity

When designers know they can quickly turn ideas into working prototypes, they’re more likely to experiment and take creative risks. Rapid prototyping encourages innovation by allowing multiple design iterations without the fear of high costs or long delays.

Whether it’s testing new materials, shapes, or mechanisms, this process gives teams the freedom to explore and improve ultimately leading to better, more innovative products.

4. Saving Costs in the Long Run

While prototyping might seem like an added expense, it’s actually one of the smartest investments a company can make. Early testing helps avoid costly errors during production, such as tool modifications, defective parts, or wasted materials.

By validating designs early through rapid prototyping services, businesses reduce production waste, minimize rework, and ensure a smoother, more cost-effective path to manufacturing.

5. Enhancing Communication and Collaboration

Having a tangible prototype in hand transforms how teams communicate. Engineers, designers, investors, and clients can all see and interact with the product, not just view it on a screen.

This improves collaboration, aligns expectations, and builds confidence at every stage of development. It also helps sales and marketing teams visualize and demonstrate products even before full production begins.

6. Supporting Customization and Low-Volume Production

Modern markets increasingly demand personalization and small-batch production. Rapid prototyping services support this trend perfectly.

With technologies like CNC machining and additive manufacturing, companies can create one-off prototypes or small production runs with high precision and consistent quality. This flexibility allows manufacturers to respond quickly to customer needs without major retooling or setup costs.

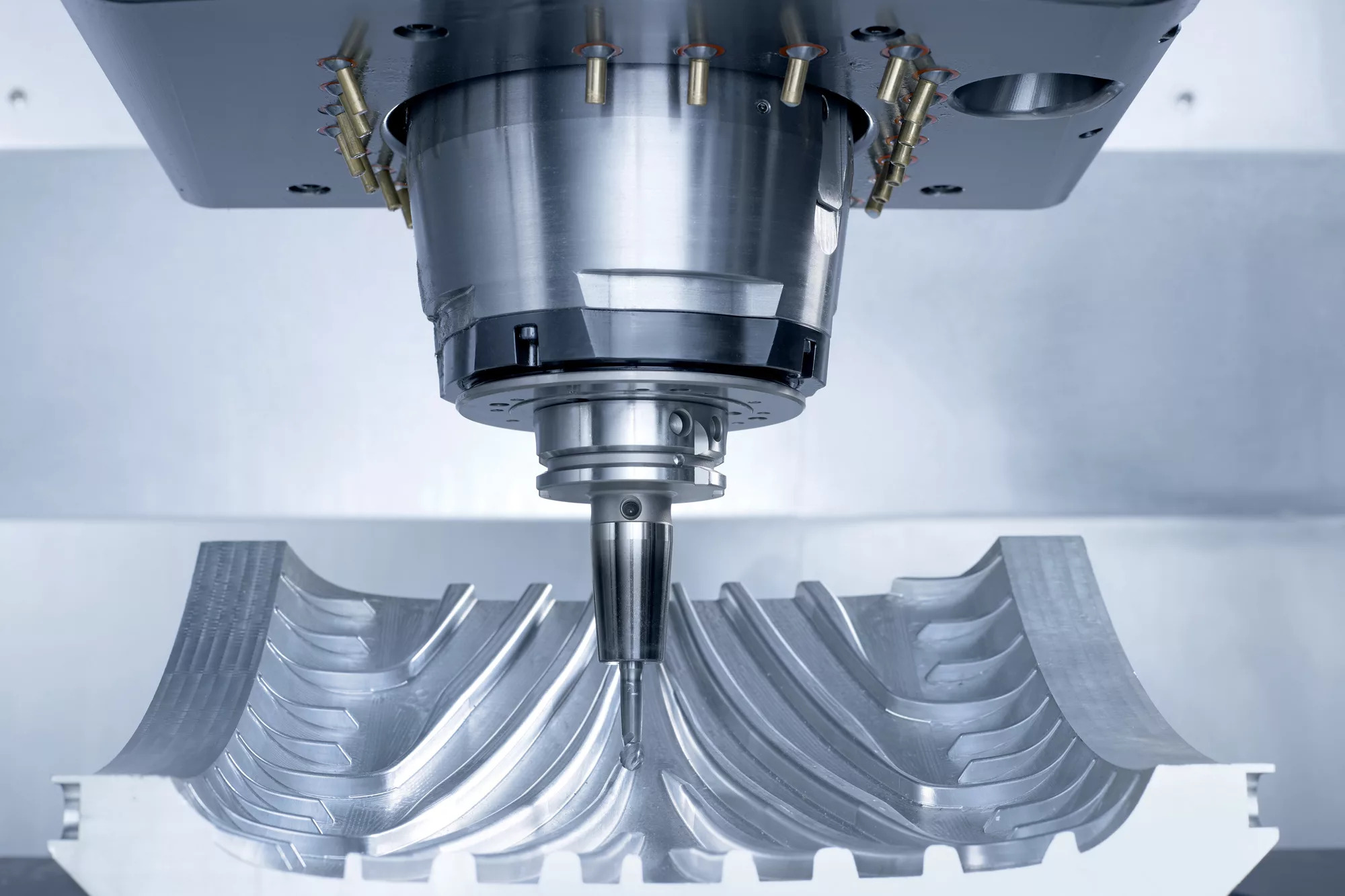

How CNC Machining Enhances Rapid Prototyping

While 3D printing is often associated with rapid prototyping, CNC machining remains one of the most reliable and precise methods, especially for functional prototypes that require tight tolerances or production-grade materials.

CNC machining offers superior accuracy, a wide material selection (metals, plastics, and composites), and excellent surface finishes. It’s ideal for creating prototypes that behave exactly like the final product perfect for testing durability, performance, and assembly.

By combining CNC technology with rapid prototyping services, businesses gain both speed and precision, two elements essential to modern product success.

The Future of Product Development Relies on Rapid Prototyping

As industries embrace digital transformation, rapid prototyping continues to evolve. From AI-driven design optimization to advanced 5-axis CNC machining, the future promises even faster turnaround times, improved accuracy, and greater material versatility.

For businesses, the message is clear: rapid prototyping isn’t just a helpful step, it’s an essential part of staying competitive, innovative, and efficient in today’s market.

Conclusion: Bring Your Ideas to Life with CNC TUOWEI

Modern product development demands speed, precision, and adaptability and that’s exactly what rapid prototyping services deliver. Whether you’re refining a new concept, testing functionality, or preparing for full-scale production, rapid prototyping bridges the gap between imagination and reality.

Visit TUOWEI, we specialize in delivering high-quality rapid prototyping and CNC machining solutions that empower businesses to design, test, and launch products faster than ever before. Our advanced equipment, skilled technicians, and strict quality control ensure your prototypes meet the highest standards of accuracy and performance.

Ready to bring your product idea to life?

Explore precision machining options for professional rapid prototyping services that turn innovation into reality, quickly, precisely, and efficiently.